Aerodelft Blog

Proudly a partner of FEMTO Engineering, AeroDelft is a student team based in Delft. Our mission is to prove that emission-free aviation is possible by pioneering liquid hydrogen-powered electric aircraft.

Proudly a partner of FEMTO Engineering, AeroDelft is a student team based in Delft. Our mission is to prove that emission-free aviation is possible by pioneering liquid hydrogen-powered electric aircraft.

AeroDelft aims to do this by first developing a gaseous hydrogen aircraft and then upgrading it to a liquid hydrogen-powered aircraft. To achieve this, AeroDelft is modifying a Sling 4 aircraft, replacing its power train with a sustainable hydrogen power train. The aim is to fly on gaseous hydrogen in 2025 and on liquid hydrogen in 2026.

In pursuit of modifying the motor mount structure to accommodate the hydrogen powertrain, the AeroDelft structures department has been diligently working. The motor mount, a pivotal structural element affixed to the front firewall of the aircraft, plays a crucial role in offering sturdy support for various essential nose components. Beyond its foundational role, the motor mount assumes additional responsibilities, including supporting the nose landing gear and absorbing nose wheel loads during both landing and taxiing operations.

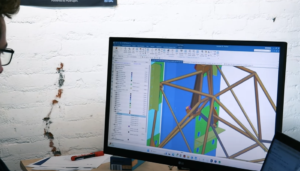

The structure encounters various critical load cases during its mission, and it must withstand the limit loads without undergoing plastic deformation. To meet the stringent performance requirements, our engineers utilize advanced software tools in the design process, such as FEM on Simcenter 3D. This tool enables simulations of the various load cases, streamlining the design iterations and capturing ultimate load responses for certification.

FEMTO provides our engineers with assistance with the Motor Mount FEM analysis, given their expertise in Simcenter 3D. Regular meetings with them have enhanced our comprehension of the software, enabling us to refine our models for highly accurate simulations of real-life cases. Subsequent to the limit load test campaign, the strain data analysis was utilized to verify the FEM models available

FEMTO provides our engineers with assistance with the Motor Mount FEM analysis, given their expertise in Simcenter 3D. Regular meetings with them have enhanced our comprehension of the software, enabling us to refine our models for highly accurate simulations of real-life cases. Subsequent to the limit load test campaign, the strain data analysis was utilized to verify the FEM models available

Currently, our focus is adding more detail to the FEM model of the motor mount structure in order to have a better correlation between the simulation results to the data available from the physical testing. FEMTO’s guidance has proven invaluable in both improving and analyzing strain data derived from the models during this phase. Once the verified models are accessible, the strengths and weaknesses of the current design in withstanding critical load cases for the part will be identified, providing valuable insights for further design iterations.

With the guidance of FEMTO, a new version of the motor mount will be designed using a more accurate and reliable FEM model. Besides designing the new motor mount, FEM software will also be used to develop the mounting of the fuel cell and the hydrogen tank. Stay tuned!

P.S. Check out our YouTube video for a more detailed explanation of the Motor Mount application in our project:

Do you need more information or want to discuss your project? Reach out to us anytime and we’ll happily answer your questions.

At Femto Engineering we help companies achieve their innovation ambitions with engineering consultancy, software, and R&D.

We are Siemens DISW Expert Partner for Simcenter Femap, Simcenter 3D, Simcenter Amesim, Simcenter STAR-CCM+ and SDC verifier. Get in touch and let us make CAE work for you.

Sign up for our newsletter to get free resources, news and updates monthly in your inbox. Share in our expertise!