STAR-CCM+ Benchmark: Dambreak

In this article you can read the findings of a STAR-CCM+ benchmark our CFD engineers performed.

In this article you can read the findings of a STAR-CCM+ benchmark our CFD engineers performed.

Femto’s main activity is to validate designs and optimize the performance of systems, structures, and products with help of simulations. Detecting flaws in the design prior to physical testing can lead to significant cost savings. The efficacy of simulation technology depends on how well the simulation matches real-word conditions. In our experience engineers are very curious and can be wary of the sometimes black-box nature of simulation software. To gain confidence in your model and methods benchmarks play an important role.

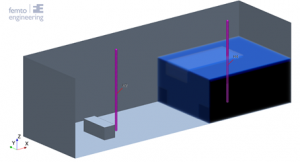

The dambreak experiment, as performed by MARIN, is used as a testcase to verify the behavior of water in a STAR-CCM+ CFD simulation. The experiment consists of a tank with a retractable door behind which a body of water is present. When this door is rapidly retracted the water will start moving due to gravity. A three-dimensional simulation has been set up with STAR-CCM+ 2020.1 using the same geometry and water starting location as was used in the test to verify the water behavior predicted by STAR CCM+.

The case consists of a tank with a length of 3.22m and a width and height of 1m. As an initial condition the water is present in a cube from x = 2m (total length of 1.22m), a width of 1m and a height of 0.55m. At x = 0.67m a box is present with a length of 0.16m, a width of 0.4m and a height of 0.16m.

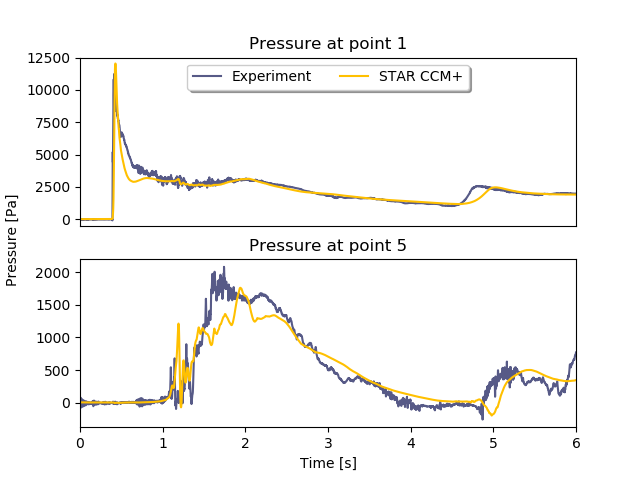

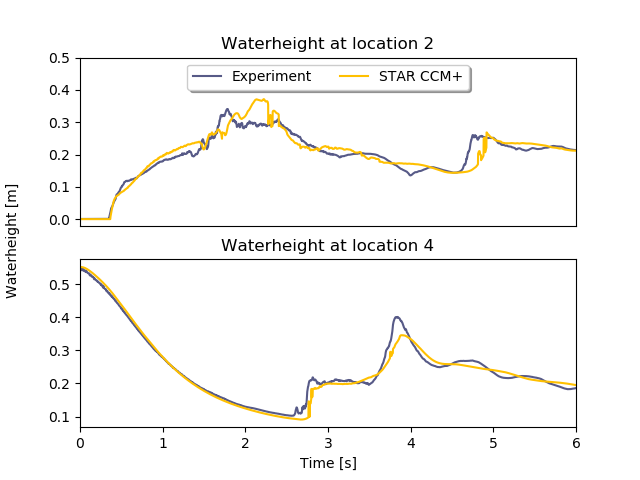

At t = 0 the water is released and can flow freely towards the box. In the experiment the pressure is measured at eight points (P1-P8) where four points are present on the back of the box and four points are present on the top of the box. For the comparison only points 1 and 5 (P1, P5) are used. The water height is measured at four locations in the experiment, for the comparison two locations are used, location 2 (at x = 1m, H2) and location 4 (at x = 2.66m, H4).

In STAR-CCM+ use is made of the volume of fluid (VOF) model using both water and air.

On the interval 0.5s – 6.0s, the average water height error on location 2 is 2.1%. The average error for the pressure on point 1 is 2.1% on the interval 0.5s – 6.0s. The maximum average error is found when comparing the pressure at point 5 to the measured pressure. The average pressure error on the interval 1.0s – 6.0s on point 5 is 22.3%.

The first pressure peak occurs at the same time as found in the experiment, but the pressure reduces more quickly than in the experiment. The second pressure peak (around t = 4.5s) starts a little later than in the experiment.

It can be concluded that a good comparison is present between the results of the experiment and the results of the STAR-CCM+ simulation. If you enjoyed this post and would like to get updates on our work, follow us on LinkedIn, Twitter or Youtube. We really appreciate every subscriber, comment and thumbs up. Thanks for reading and watching our videos!

Femto Engineering is smart expert partner for Siemens principal CFD solutions: Simcenter STAR-CCM+ in the Benelux. Our CFD engineers use the software daily in their consultancy projects and are therefore excellent sparring and support partners. Don’t hesitate to contact us!

Do you need more information or want to discuss your project? Reach out to us anytime and we’ll happily answer your questions.

At Femto Engineering we help companies achieve their innovation ambitions with engineering consultancy, software, and R&D.

We are Siemens DISW Expert Partner for Simcenter Femap, Simcenter 3D, Simcenter Amesim, Simcenter STAR-CCM+ and SDC verifier. Get in touch and let us make CAE work for you.

Sign up for our newsletter to get free resources, news and updates monthly in your inbox. Share in our expertise!