Reducing 15% weight for Hyva’s lifting bracket

Using topology optimization Femto engineers achieved 15% weight reduction on a lifting bracket used in the trailer tipper of Hyva lift systems.

Using topology optimization Femto engineers achieved 15% weight reduction on a lifting bracket used in the trailer tipper of Hyva lift systems.

Hyva is the market leader in the world for tipping solutions. Hyva products are used worldwide across a range of sectors including transport, construction, mining, materials handling and waste handling & recycling. Founded in 1979 in The Netherlands, Hyva is now a global company with manufacturing facilities and subsidiaries worldwide.

Femto Engineering was asked to evaluate the current lifting bracket of the Hyva trailer tipper. First we determined the strength and stiffness behavior of the part under heavy loading. Then we explored how the part could be optimized to reduce weight.

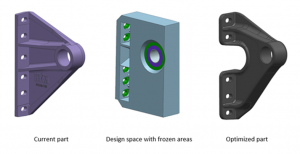

We used specialized FEM software to determine the design space; this is the area the software will optimize for. During optimization the solver will remove material from the design space that is not needed, but it cannot add material, for this reason it is important to assign a design space that is large enough for Optistruct to keep removing material until it finds the best topology.

The objective of the optimization was to find a structure with the maximum stiffness for the component with a volume restriction. Increased stiffness is achieved by minimizing the strain energy in the model.

A geometric restriction places restrictions on the changes that the solver can make to the topology. The areas in the model that are not allowed to change are defined as the frozen areas, this means that Optistruct will leave these regions as they are while using surrounding elements to find the best topology.

With the power of topology optimization Femto Engineers were able to achieve a weight reduction of 15% on the Hyva lifting bracket, while confidently meeting strength and stiffness requirements under heavy load. Find more background information on topology optimization here. Contact us if you want to hear more about our services.

Do you need more information or want to discuss your project? Reach out to us anytime and we’ll happily answer your questions.

At Femto Engineering we help companies achieve their innovation ambitions with engineering consultancy, software, and R&D.

We are Siemens DISW Expert Partner for Simcenter Femap, Simcenter 3D, Simcenter Amesim, Simcenter STAR-CCM+ and SDC verifier. Get in touch and let us make CAE work for you.

Sign up for our newsletter to get free resources, news and updates monthly in your inbox. Share in our expertise!