Simcenter Amesim | Sea routing and speed comparison

Marine simulation – Sea routing and speed comparison

Marine simulation – Sea routing and speed comparison

The rising fuel prices and ongoing efforts to minimize the environmental impact makes reducing fuel consumption one of the main challenges in maritime sector. Simcenter Amesim models can be used within the design process to evaluate drivetrain alternatives and during operations to compare sea routes based on expected weather conditions.

Examples of design compressions

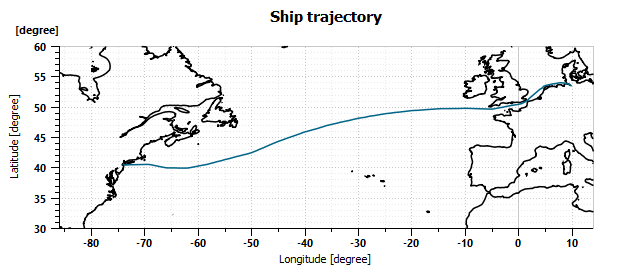

Figure 1: Ship trajectory form port of Hamburg to New Jersey

This article gives an example on how Simcenter Amesim could assist during operations. A cargo ship is about to leave the port of Hamburg with and has New Jersey as destination. The following questions need to be answered when planning the trip:

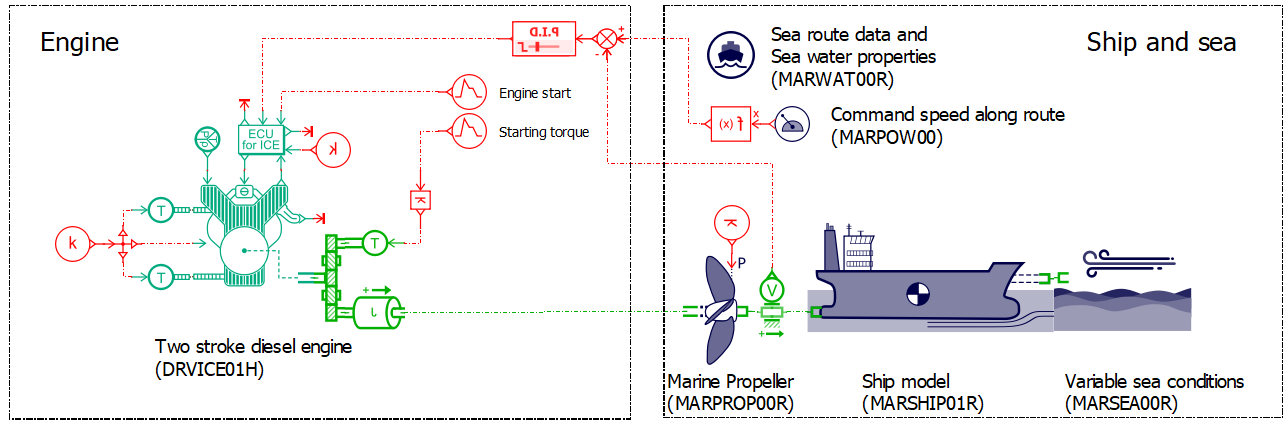

Within Simcenter Amesim a model of the ship is constructed (Figure 2). The main components are:

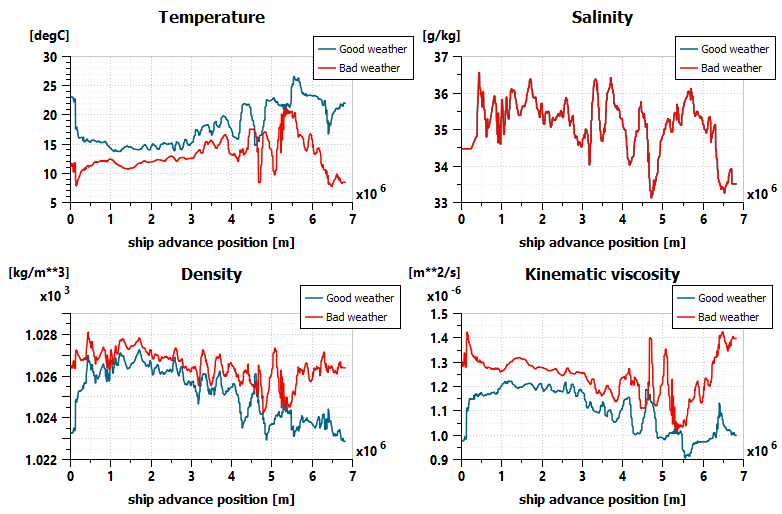

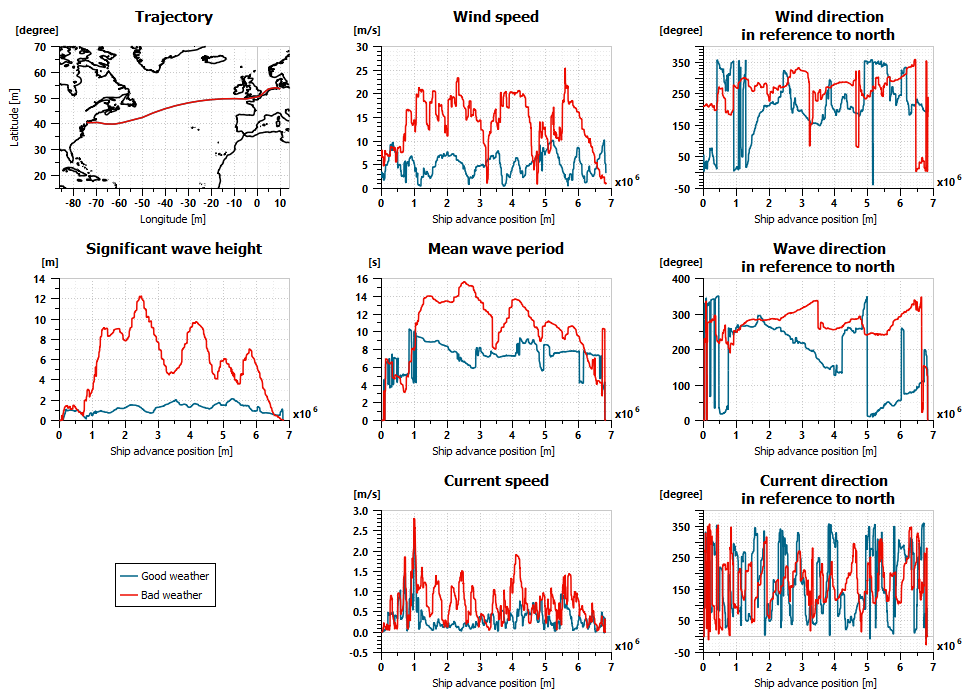

Varying sea conditions along the sea route are accounted for by apply two levels of representative weather conditions (good and bad). These levels have been established taking the average weather you may encounter on the travel and are split into two extreme levels. Figure 3 and 4 show the varying conditions.

Figure 3: Basic seawater properties for good and bad weather conditions

Figure 4: Wind and wave properties for good and bad weather conditions

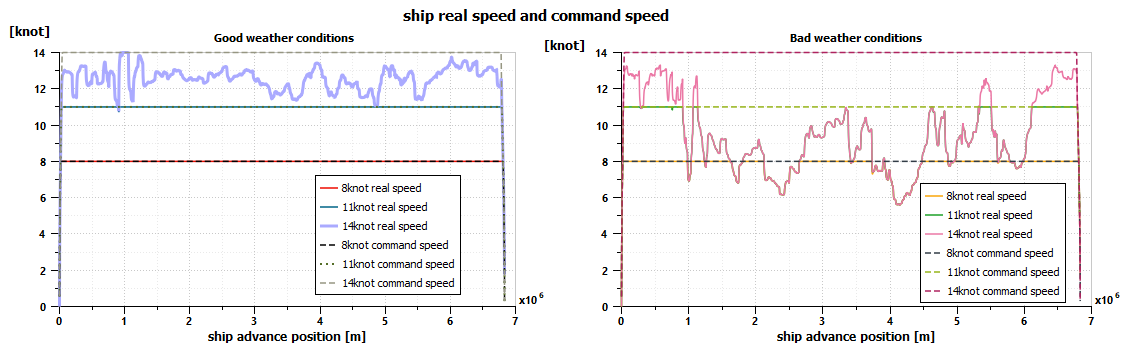

Three different command speed profiles are imposed. Based on the two levels of expected conditions and three different cruising speeds a total of six simulations are performed to determine the travel times, fuel consumptions and CO2 emissions. Figure 5 shows the real ship speed compared to the command speed. For good weather conditions the real speed follows the 8 and 11knot command speed. However, the real speed does not follow the max speed command due to the maximum load reached by ship engine. For bad weather conditions, the maximum real speed even drops below 11knot and 8knot along the route.

Figure 5: Commanded speed profiles and real ship speeds

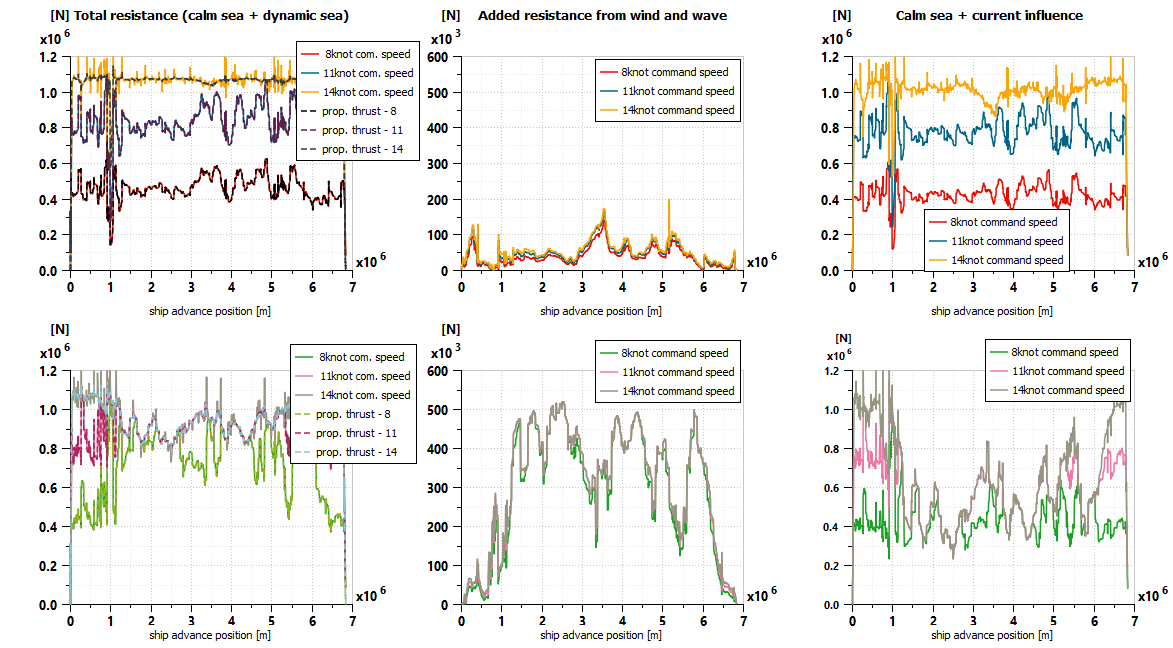

Figure 6: Sea resistances of different sources for good (top row) and bad weather conditions

The ship accelerations are computed by the resultant force on the ship divided by the mass of ship. The result force is the difference between the total resistance and propeller thrust. The forces acting on the ship are shown in Figure 6.

The travel time, total fuel consumption and CO2 emission are determined for the six simulations. Figure 7 shows how these evolve along the ship advance position. The varying speeds in the bad weather conditions are clearly visible in the travel time graph, as the slopes are not constant.

The increase in travel time and average fuel consumptions are shown in the table.

[table id=2 /]

Contact us if you’re interested in system simulation and the possible ways we can support you, or want to receive more information.

Do you need more information or want to discuss your project? Reach out to us anytime and we’ll happily answer your questions.

At Femto Engineering we help companies achieve their innovation ambitions with engineering consultancy, software, and R&D.

We are Siemens DISW Expert Partner for Simcenter Femap, Simcenter 3D, Simcenter Amesim, Simcenter STAR-CCM+ and SDC verifier. Get in touch and let us make CAE work for you.

Sign up for our newsletter to get free resources, news and updates monthly in your inbox. Share in our expertise!