Data center comparison CFD STAR CCM+ with paper

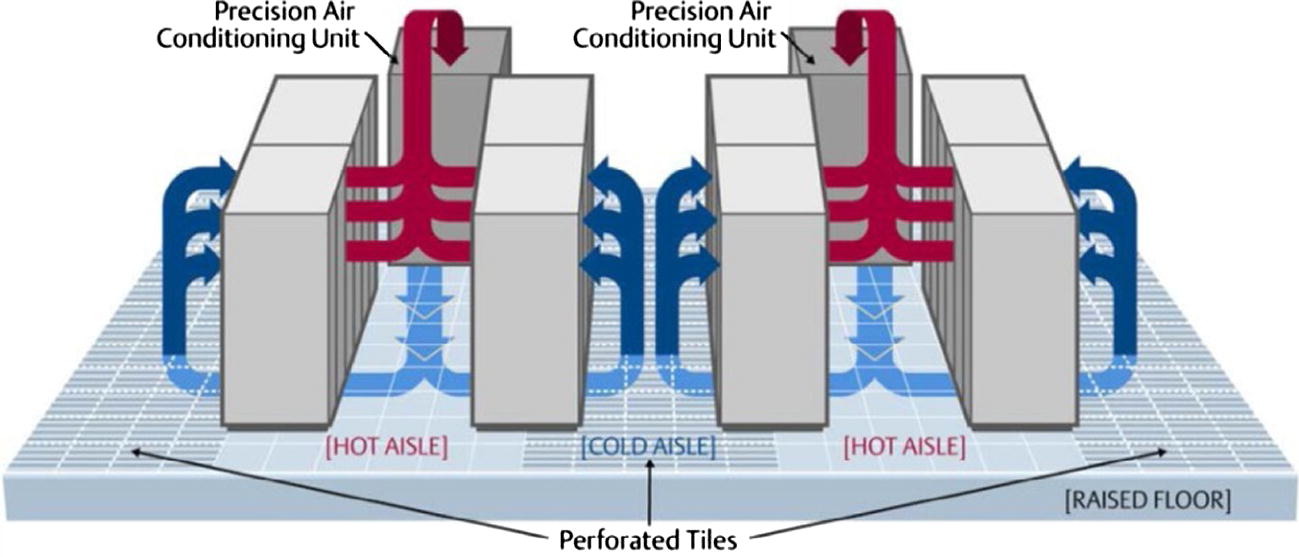

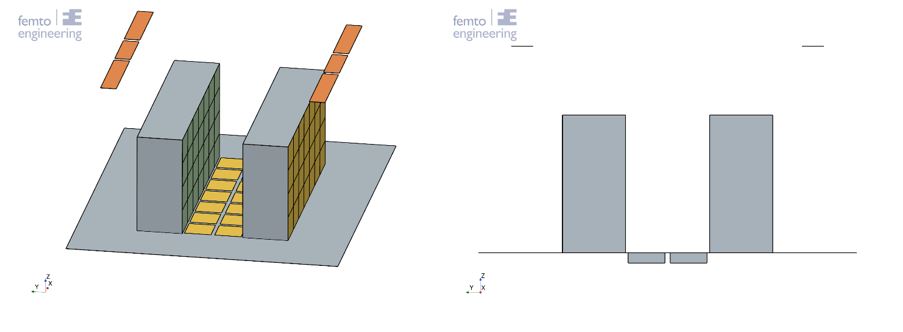

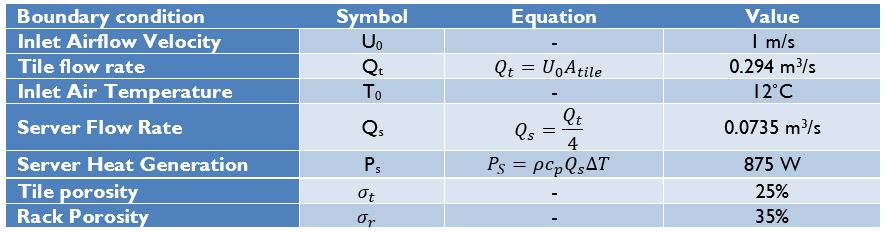

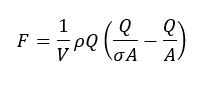

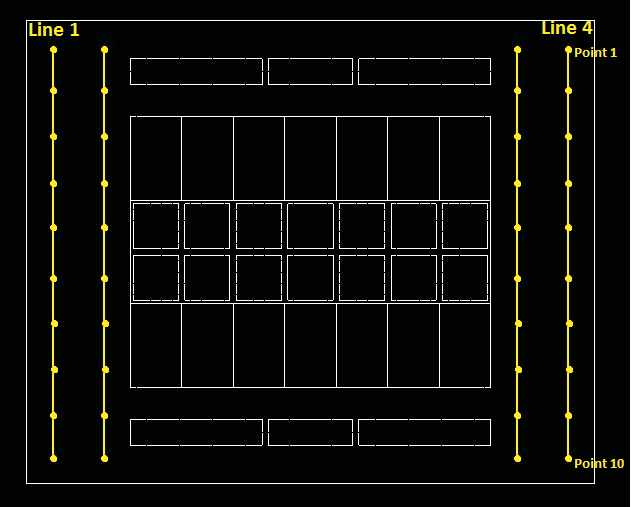

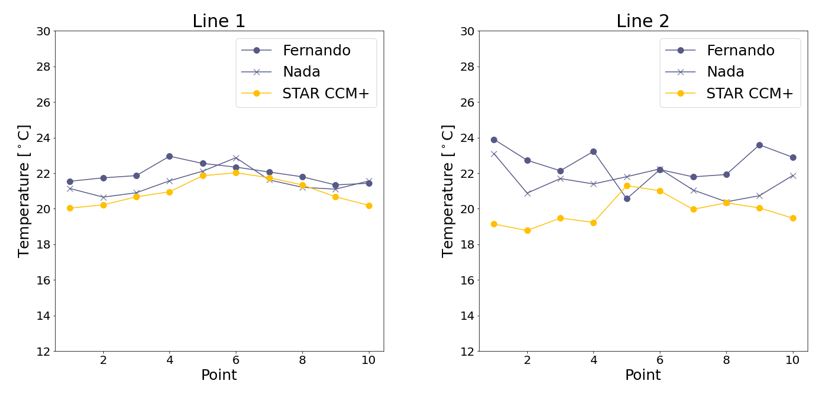

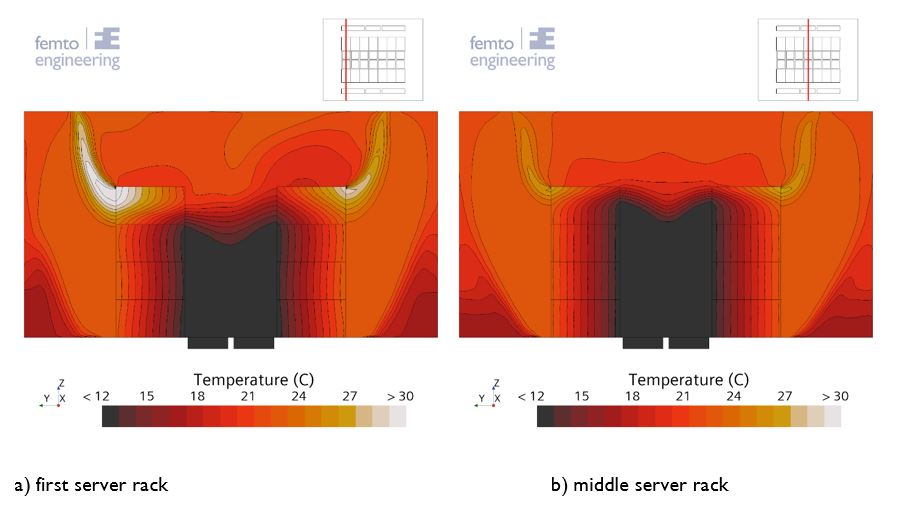

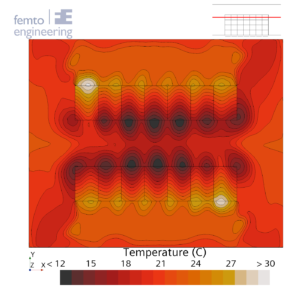

In this article we have compared a simulation of a data center with a similar simulation performed by (Fernando, Siriwardana, & Halgamuge, 2012). This paper introduces a data center containing 14 racks with 4 server units each. It researches the effect of scaling of a data center on the cooling within the data center. Another paper was used as well, namely (Nada, Said, & Rady, 2016), which reproduced the results from (Fernando, Siriwardana, & Halgamuge, 2012) as well as researching the effect of different types of Computer Room Air Conditioning (CRAC) configurations as well as a closed and an open cold Aisle.