FEA on silicone breast implants

A Femto Engineering Case Study

A Femto Engineering Case Study

Although it was a while ago we performed several analyses on breasts implants for our client Mentor Medical we like to share as much practices as possible of FEA outside of traditional application fields.

Founded in 1969, Mentor Worldwide LLC is a leading supplier of medical products for the global aesthetic medicine market. The Company develops, manufactures, and markets innovative, science-based products for aesthetics markets around the world.

Mentor has made breast implant devices for more than 20 years. Mentor’s breast implants are for use in both breast augmentation and breast reconstruction and are of the highest quality, and made under strict standards of design and testing.

Mentor has made breast implant devices for more than 20 years. Mentor’s breast implants are for use in both breast augmentation and breast reconstruction and are of the highest quality, and made under strict standards of design and testing.

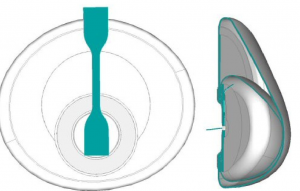

A breast implant is a prosthesis used to change the size, shape, and contour of a person’s breast. Since ruptures are a risk, R&D naturally focusses on reducing this risk factor. In its production process, different layers of different types of silicone rubber (patches) are vulcanized. Vulcanization is a chemical process for converting natural rubber or related polymers into more durable materials by the addition of sulfur or equivalent curatives.  Special attention is needed into the effects of this transitional process on the strength, elasticity and durability of the material. Tests are carried out with samples from the back of the implants which are placed in a tensile tester under large deformations.

Special attention is needed into the effects of this transitional process on the strength, elasticity and durability of the material. Tests are carried out with samples from the back of the implants which are placed in a tensile tester under large deformations.

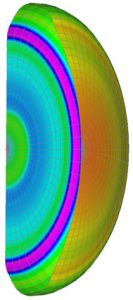

Mentor Medical Leiden asked Femto Engineering to gain more insights into this transitional process. Using non-linear analyses we calculated the strength and deformation of the implants by simulating several stretch scenarios. We used Femap/NX Nastran for this assignment. To gain insight in the increase of stresses and deformations we performed the analyses with large deformations up to 300%.  We used a material model specifically suited for modeling (silicone) rubber. Lastly we did a comparative performance study between a representative implant sample of Mentor Medical and another manufacturer. Mentor Medical implants scored overall better in performance.

We used a material model specifically suited for modeling (silicone) rubber. Lastly we did a comparative performance study between a representative implant sample of Mentor Medical and another manufacturer. Mentor Medical implants scored overall better in performance.

We hope you liked this case study. Want to hear more? Contact us! Also if you are interested in our analyzing, simulation or optimization services, get in touch!

Do you need more information or want to discuss your project? Reach out to us anytime and we’ll happily answer your questions.

At Femto Engineering we help companies achieve their innovation ambitions with engineering consultancy, software, and R&D.

We are Siemens DISW Expert Partner for Simcenter Femap, Simcenter 3D, Simcenter Amesim, Simcenter STAR-CCM+ and SDC verifier. Get in touch and let us make CAE work for you.

Sign up for our newsletter to get free resources, news and updates monthly in your inbox. Share in our expertise!