Learning CFD from industry experts: Eduardo’s graduation internship at Femto

“From expert technical guidance to an open and welcoming team culture, Femto Engineering provided an ideal environment for my graduation internship.”

“From expert technical guidance to an open and welcoming team culture, Femto Engineering provided an ideal environment for my graduation internship.”

Remember Eduardo Izarra, our Intern Engineer who joined us in September 2025? Time flies, and his internship has soon come to an end. During his graduation internship at Femto Engineering, Eduardo explored the world of CFD and combustion modelling, using Siemens STAR-CCM+. In this interview, he looks back on his journey and the key insights gained along the way.

As part of my graduation internship, I joined Femto Engineering as a Project Engineer Intern, where I worked on CFD and combustion modeling using Siemens STAR-CCM+. During this internship, I combined academic research with hands-on engineering practice, while learning from experienced professionals in a supportive and international work environment.

The support from my supervisors and colleagues has been outstanding, from deep technical discussions about fluid dynamics to friendly conversations during after-lunch walks and the Thursday/Friday end-of-week drinks.

The guidance I received for my graduation research was invaluable, especially considering that I had never worked with CFD before. I would like to thank my supervisors, Martijn and Sebastian, for their continuous assistance, clear explanations, and mentoring throughout the months.

I also want to thank my colleague Daniel for helping with meshing challenges and for providing another point of view whenever needed.

During my bachelor’s studies, I mainly covered the foundational theory required for CFD. This internship was my first opportunity to apply that knowledge in practice and explore the field in depth. CFD proved to be a versatile discipline with applications across many industries, and I am glad I gained hands-on experience that will benefit my future career.

I had been following Femto Engineering on LinkedIn for some time when I came across their internship opportunities. At university, I had only simulated basic structural deformations, and when I discovered the CFD content shared by Femto, it truly amazed me. I knew such simulations existed, but I had little awareness of the engineering applications behind them and the extensive background knowledge they require.

I applied for three graduation internships at Femto and was eventually interviewed for the CFD combustion internship. While I had no specific preference initially, my previous semester experience in propulsion and gas turbines in aviation played an important role in the final selection.

My graduation assignment focused on validating combustion models in STAR-CCM+ using two well-known benchmark experiments:

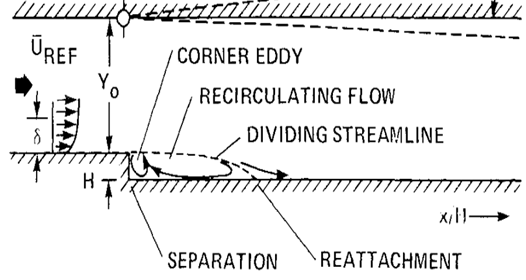

The first was the Backward-Facing Step reacting flow by Pitz and Daily (1981), which investigates the effects of sudden flow expansion on combustion in a turbulent premixed flame. Selecting appropriate turbulence and combustion models was a key challenge in this case.

Diagram 1. Backward-facing step cross section and flow direction. Recirculation after step.

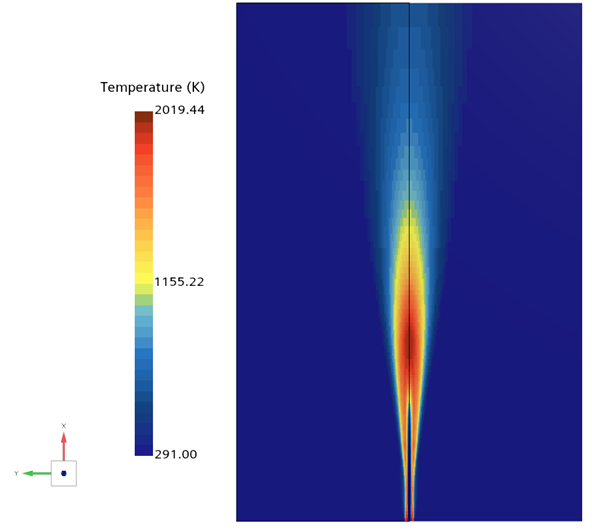

The second benchmark was the Sandia Laboratories Diffusion Flame D (1996), where the goal was to reproduce a turbulent methane/air diffusion flame and evaluate parameters such as species concentrations (methane, CO, O₂) and temperature distribution.

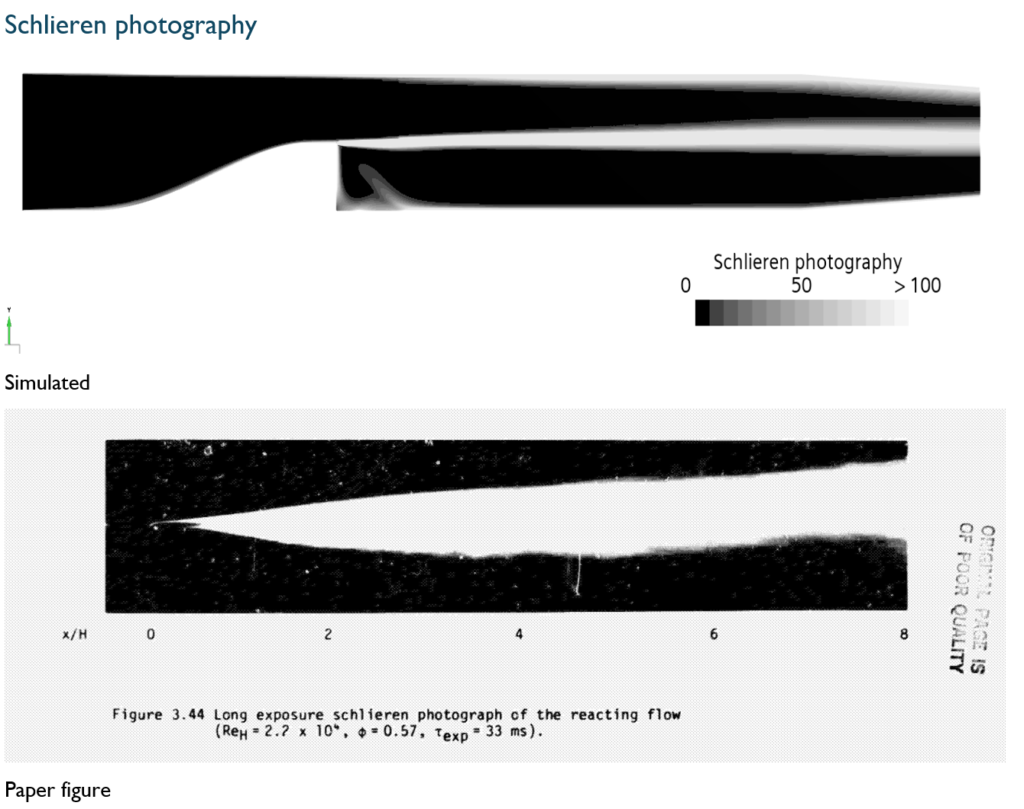

Diagram 2. Backward-Facing Step schlieren photo simulation vs paper. This is the only visual of the flame available in the original paper.

Figure 1. The sandia flame D experiment. Temperature scene of simulated Sandia Flame D

The insights gained from these benchmarks are highly valuable for future combustion-related projects at Femto across different industries. Personally, I enjoyed working on a challenging topic and overcoming the steep learning curve, especially as a student with no prior CFD experience.

As a first-time user, I found STAR-CCM+ to be a strong all-in-one solution for CFD applications. Although the learning curve was steep, the documentation and tutorials greatly supported my learning process. Within approximately three weeks to one month, I became comfortable with the software’s interface and workflow.

I am very glad I had the opportunity to complete my graduation internship at Femto Engineering. It contributed significantly to my professional development and gave me insight into the work culture of a Dutch, yet highly international, engineering company. Learning such a complex topic firsthand from industry experts made this a unique and rewarding experience.

We would like to thank Eduardo for is valuable contribution and enthusiasm during his internship at Femto Engineering. His work reflects our commitment to technical excellence, knowledge sharing and supporting young engineers on their endeavours.

At Femto Engineering, we are always open to supporting talent. Want to learn more about our team and work culture? Stay tuned for upcoming internship and career opportunities.

Do you need more information or want to discuss your project? Reach out to us anytime and we’ll happily answer your questions.

At Femto Engineering we help companies achieve their innovation ambitions with engineering consultancy, software, and R&D.

We are Siemens DISW Expert Partner for Simcenter Femap, Simcenter 3D, Simcenter Amesim, Simcenter STAR-CCM+ and SDC verifier. Get in touch and let us make CAE work for you.

Sign up for our newsletter to get free resources, news and updates monthly in your inbox. Share in our expertise!