Femto Engineering & Project MARCH

How do you make an exoskeleton that is strong enough? Can carry forces? And it is also not too heavy?

How do you make an exoskeleton that is strong enough? Can carry forces? And it is also not too heavy?

These were the questions the Frame Engineers at Project MARCH are working on. As Femto Engineering, we have over 24 years of experience with these kinds of issues, and thus perfect for supporting the Frame Engineers of Project MARCH. How the Femto Engineering engineers gave Project MARCH advice and what they did with it, you can read in this blog.

A linear analysis uses the finite element method (FEM) to show how a part will behave when certain loads are applied. Marco first explained how to do a linear analysis on one of the frame parts designed by the previous team.

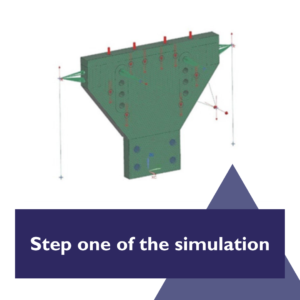

For this, Savanne and Sebastiaan uploaded the part to Simcenter 3D and learned how to prepare it for a simulation. This included creating an idealized part. Creating an idealized part means simplifying the part by removing things such as fillets and chamfers that don’t influence the strength or stiffness of the part but would increase the time required to solve the simulation. Next, they created a mesh. A mesh is essentially splitting a part up into many small triangles that will each be approached as a spring when using FEM.

For this, Savanne and Sebastiaan uploaded the part to Simcenter 3D and learned how to prepare it for a simulation. This included creating an idealized part. Creating an idealized part means simplifying the part by removing things such as fillets and chamfers that don’t influence the strength or stiffness of the part but would increase the time required to solve the simulation. Next, they created a mesh. A mesh is essentially splitting a part up into many small triangles that will each be approached as a spring when using FEM.

After that, they specified the material and placed forces and moments on the part. They then ran the simulation, of which the results showed them how the part will bend under these loads and the internal stresses that are created. These results could then be used to check if the part will not permanently deform or break.

After that, they specified the material and placed forces and moments on the part. They then ran the simulation, of which the results showed them how the part will bend under these loads and the internal stresses that are created. These results could then be used to check if the part will not permanently deform or break.

With this gained knowledge Savanne and Sebastiaan were able to validate the design of the hip and lower leg.

Marco gave Savanne and Sebastiaan another workshop on topology optimization to show them how they could set up requirements and limits and use Simcenter to optimize their design. This was done to find out how they could make the backplate for the MARCH VI exoskeleton as light as possible.

During this workshop, they again used the part from the MARCH V exoskeleton. Marco showed them how to do topology optimization for both a 2D and 3D model.

|

|

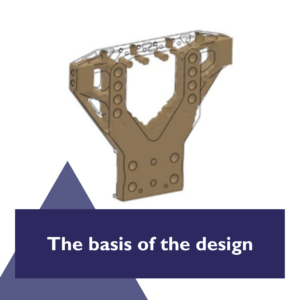

Using the knowledge Savanne and Sebastiaan had gained from Marco, they designed their backplate. This time they started with a very simple base model that met all their requirements, such as the size and shape required to hold all the electronics in the backpack. Once again, they meshed the part and specified materials, forces, and moments.

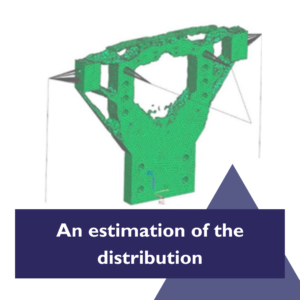

The backplate needs to be able to carry the weight of the pilot and withstand the force placed upon it by the joints. The base model for the backplate had a weight of about 1 kg. They wanted to reduce this weight as much as possible. So, they set a limit of 500 gr and ran a simulation during which Simcenter ran through dozens of cycles to determine how the material can best be placed to get the strongest and stiffest part possible.

These results were used to inspire the design for the backplate. They then validated their designs using linear analyses, which they learned earlier.

|

|

The workshops and the software have helped to optimize the backpack of the exoskeleton and validate the new designs. Now the Frame Engineers are going to simulate and test the entire exoskeleton in Simcenter. This will give them new insights into the design of the exoskeleton. Femto Engineering will keep providing tailor-made workshops for Project MARCH to help them keep innovating every year.

Want to know more on how Femto Engineering an help you with optimization or other engineering challenges? Contact us if you’re interested in our engineering consultancy and the possible ways we can support you or want to receive more information.

Do you need more information or want to discuss your project? Reach out to us anytime and we’ll happily answer your questions.

At Femto Engineering we help companies achieve their innovation ambitions with engineering consultancy, software, and R&D.

We are Siemens DISW Expert Partner for Simcenter Femap, Simcenter 3D, Simcenter Amesim, Simcenter STAR-CCM+ and SDC verifier. Get in touch and let us make CAE work for you.

Sign up for our newsletter to get free resources, news and updates monthly in your inbox. Share in our expertise!